Research, development and innovation

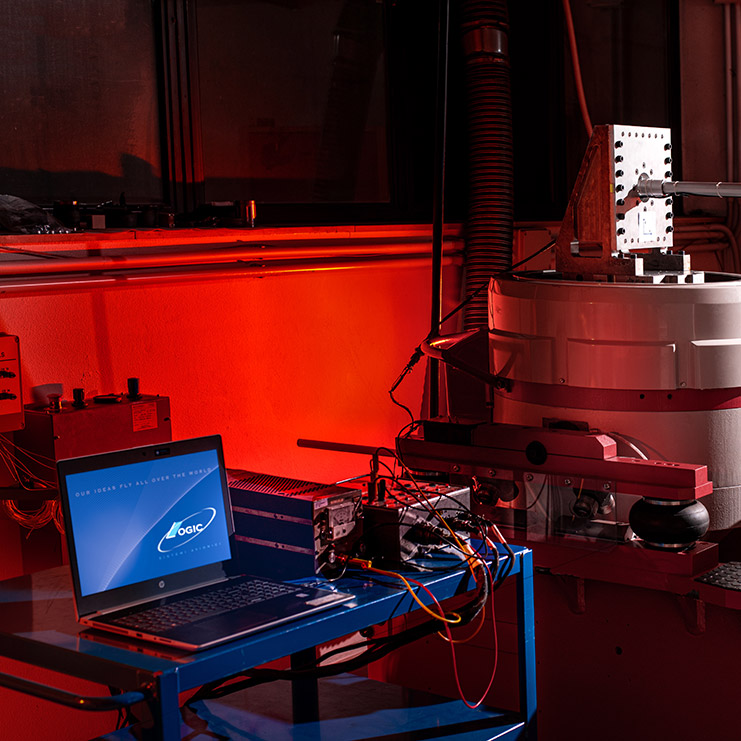

Benefiting from decades of experience and familiarity with the latest technology, LOGIC is able to promptly respond to customers’ demands providing highly professional concurrent engineering throughout the design and development phases.

Such an approach enabled LOGIC to become supplier to many of the major European and overseas manufacturers of fixed and rotary-wing aircraft, guaranteeing support on all its products throughout their service life.

LOGIC’s specialized and skilled staff is accustomed to exploiting the most recent engineering techniques.

Concurrent engineering is standard design practice in the Company, performing functions such as feasibility studies, Hardware and Software development, R&M, production of manufacturing drawings and definition of tooling and special production processes.

Hardware

- Microprocessor Systems based on 8/16/32 bit architectures

- Equipment based on Programmable Devices

- Data Acquisition and Processing Systems

- Display Systems

- NVG Compatible Panels and Displays

- Fuel Quantity Sensors and Systems

- Actuator Control Equipment

- Electric Power Control and Distribution Equipment

- Development of Hardware according to RTCA/DO254

- EMC/EMI and Lightning proof Equipment

Software

- “C” High Level Language and ADA

- Coding according MISRA guidelines

- Development of Software according to TCA/DO178 B/C

- Software Validation for Military and Commercial applications

R&M

- Stress Analysis

- Reliability Prediction

- Fault Tree Analysis

- FMECA

- Safety Analysis

- Maintainability Analysis

- Testability Analysis

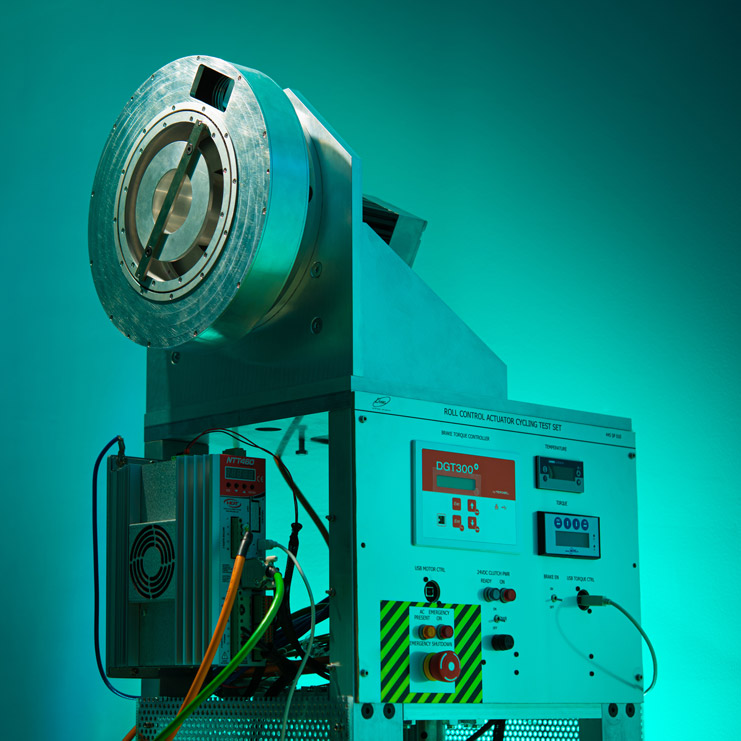

Test equipment design

- Manual Test Equipment

- Automatic Test Equipment

- Development of Code in “C++”

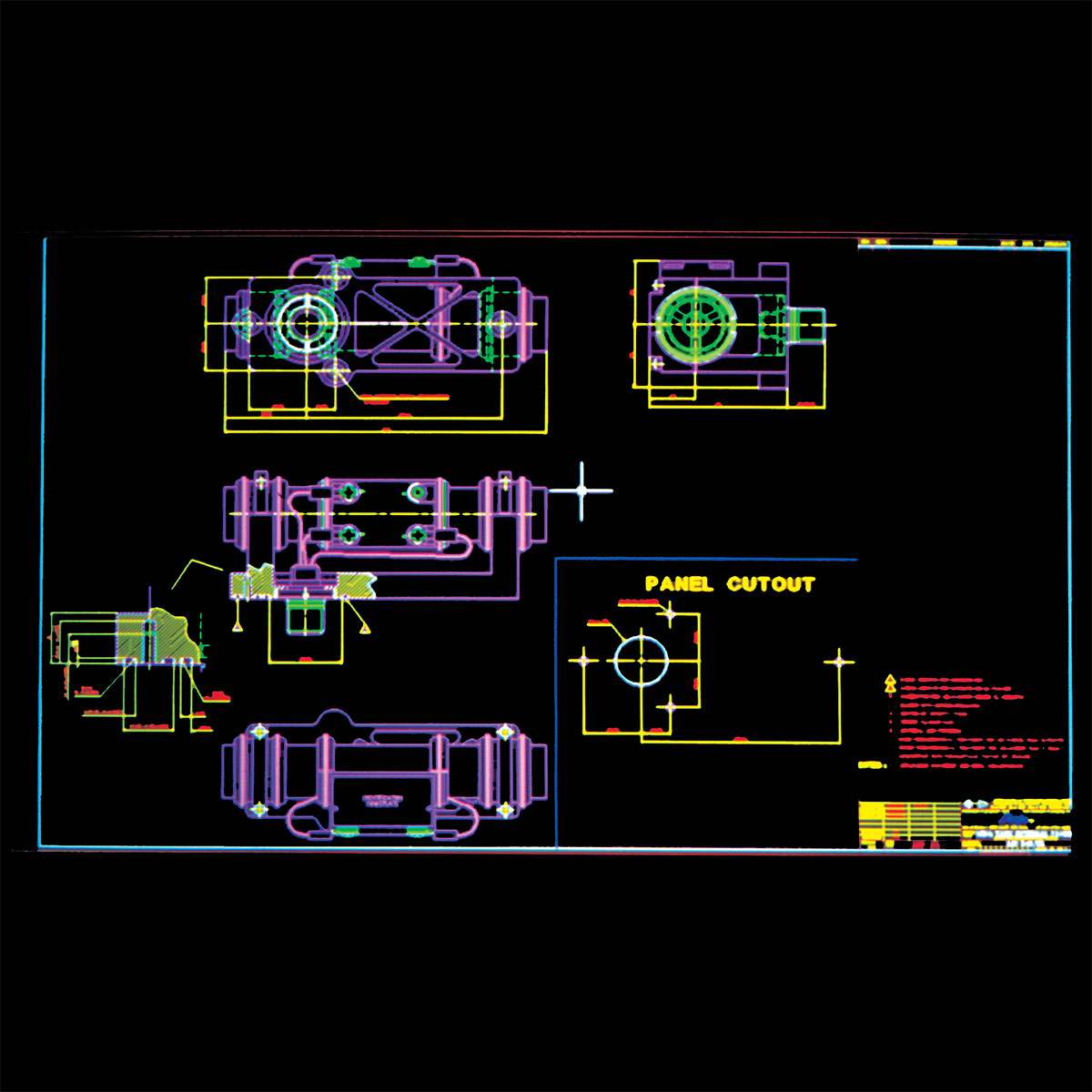

Mechanical Design

- 3D Design using Inventor Tool - Autodesk Product

- Housing and Display Panels

- Electrical Actuators

- Engine and Landing Gear Control Levers

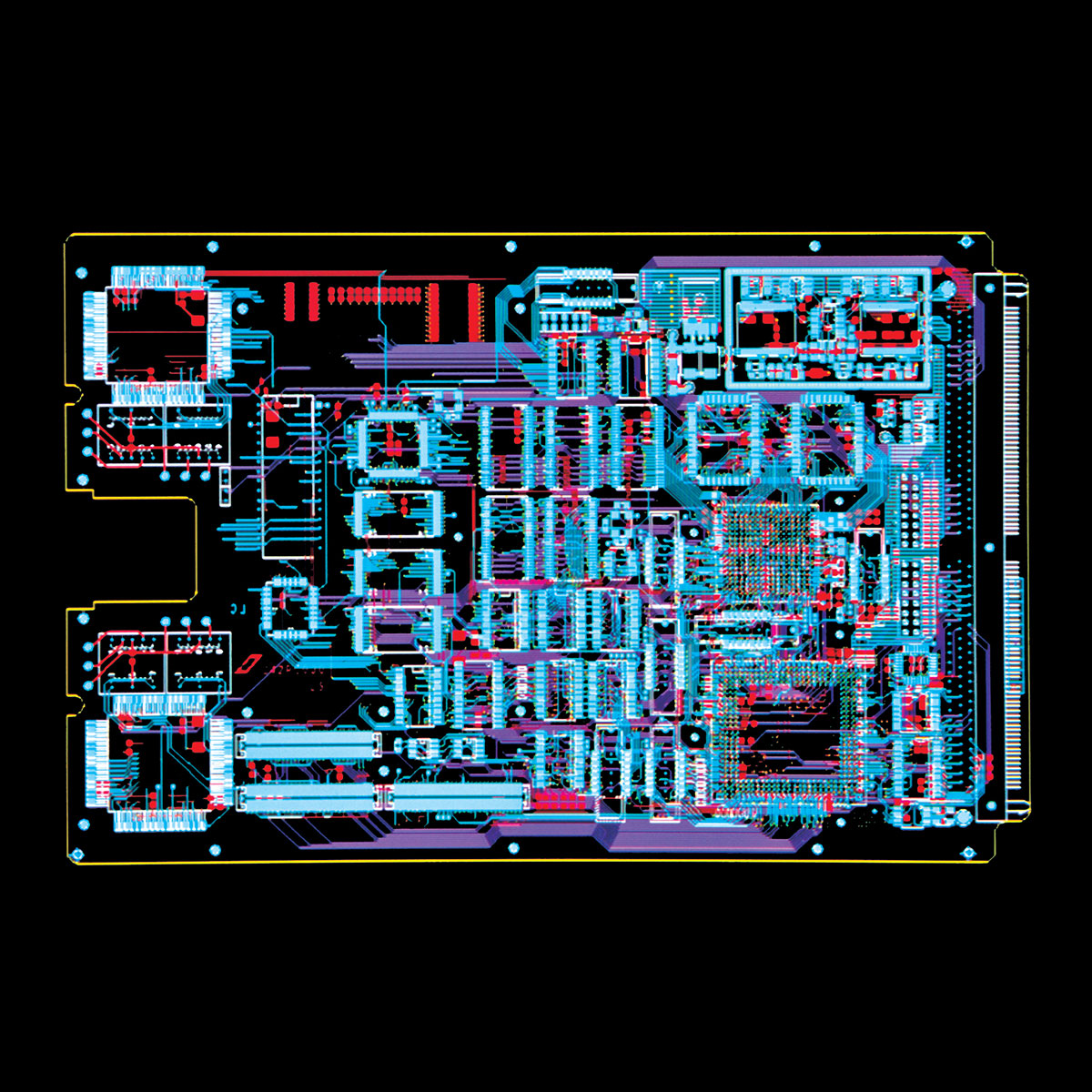

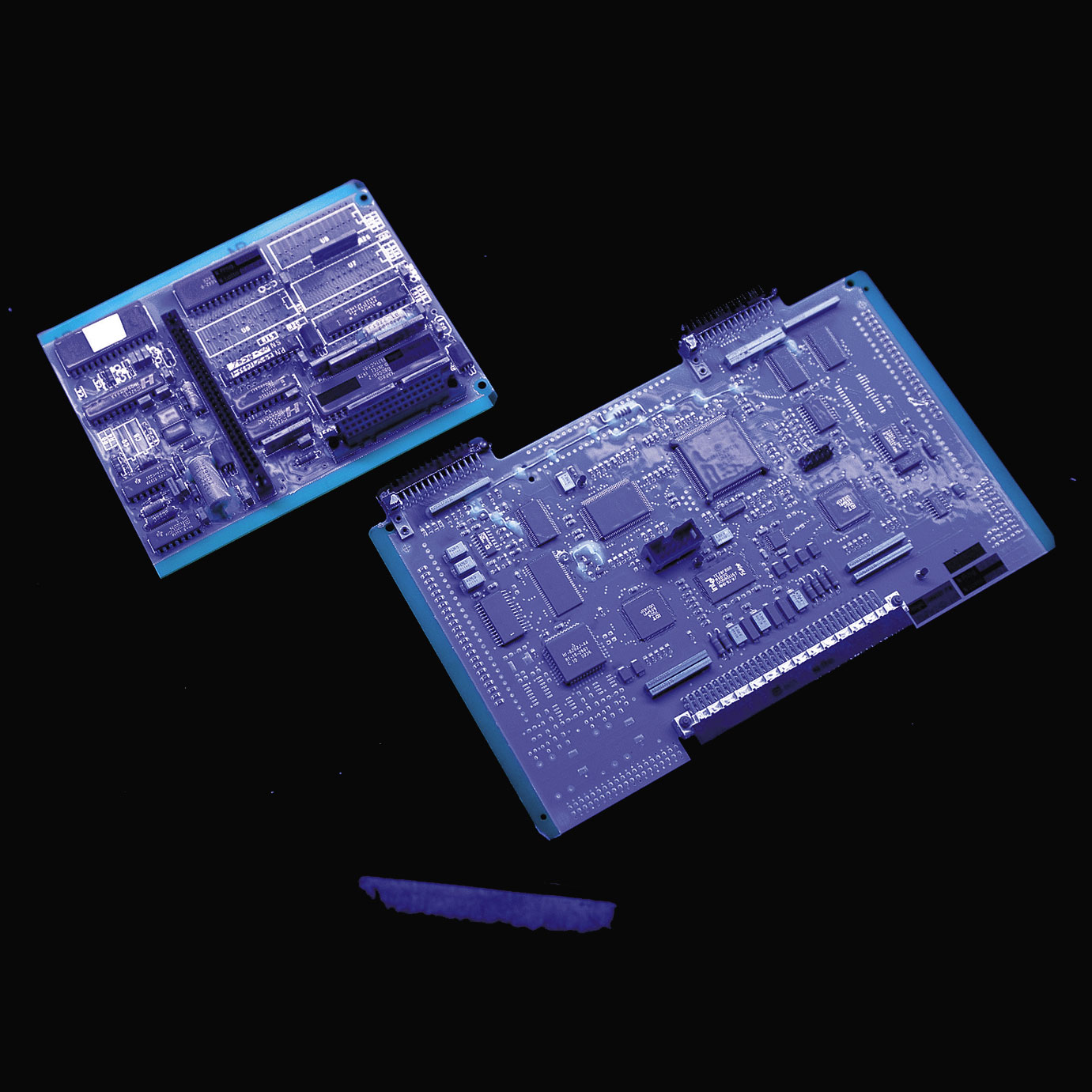

PCB Design

- Standard and Multi-layer PCBs

- Mother Boards

- Rigid-Flex Interconnections